The Significance Of Viscosity In Cosmetics: Measuring The Flow Of Beauty

The Significance of Viscosity in Cosmetics: Measuring the Flow of Beauty

Related Articles: The Significance of Viscosity in Cosmetics: Measuring the Flow of Beauty

Introduction

With great pleasure, we will explore the intriguing topic related to The Significance of Viscosity in Cosmetics: Measuring the Flow of Beauty. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The Significance of Viscosity in Cosmetics: Measuring the Flow of Beauty

- 2 Introduction

- 3 The Significance of Viscosity in Cosmetics: Measuring the Flow of Beauty

- 3.1 Why Viscosity Matters in Cosmetics

- 3.2 Techniques for Measuring Viscosity in Cosmetics

- 3.3 Factors Affecting Viscosity Measurement

- 3.4 Importance of Viscosity Measurement in Cosmetic Product Development

- 3.5 FAQs on Viscosity Measurement in Cosmetics

- 3.6 Tips for Measuring Viscosity in Cosmetics

- 3.7 Conclusion

- 4 Closure

The Significance of Viscosity in Cosmetics: Measuring the Flow of Beauty

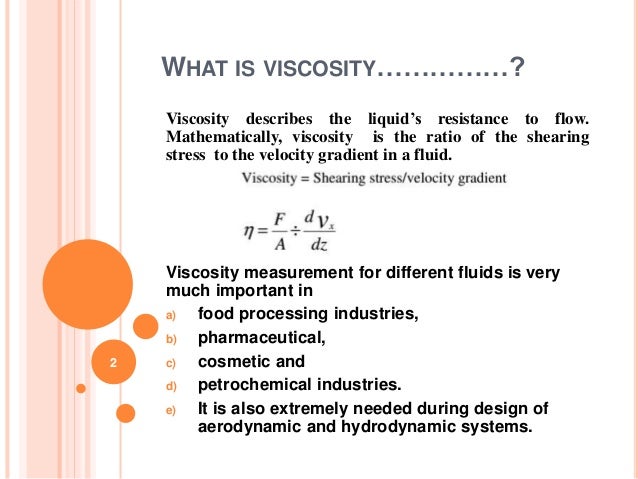

Viscosity, a measure of a fluid’s resistance to flow, plays a crucial role in the performance and appeal of cosmetic products. It dictates how easily a product spreads, its texture, and its ability to adhere to the skin. Understanding and accurately measuring viscosity is essential for cosmetic manufacturers to ensure consistent quality, optimize product formulation, and achieve desired consumer experiences.

Why Viscosity Matters in Cosmetics

The impact of viscosity on cosmetic products is multifaceted:

1. Sensory Appeal:

- Creaminess and Spreadability: Viscous products like creams and lotions feel luxurious and hydrating, allowing for easy application and distribution on the skin. A well-balanced viscosity ensures smooth application without feeling heavy or greasy.

- Texture and Consistency: Viscosity contributes to the overall texture of a cosmetic product. It can differentiate between a light serum, a rich moisturizer, or a thick mask, influencing consumer perception and preference.

- Sensory Experience: The flow characteristics of a product contribute to its sensory experience. A product with a pleasing viscosity can enhance the application process, creating a positive association and a sense of luxury.

2. Product Performance:

- Adhesion and Coverage: A suitable viscosity allows the product to adhere to the skin surface, providing effective coverage and ensuring that active ingredients remain in contact with the skin for optimal absorption.

- Stability and Shelf Life: Viscosity influences the stability of a product over time. A properly formulated viscosity can prevent separation, sedimentation, or changes in texture, ensuring the product remains effective and appealing throughout its shelf life.

- Delivery of Active Ingredients: Viscosity can affect the release and penetration of active ingredients. A well-controlled viscosity can ensure the delivery of active ingredients to the target area, maximizing their effectiveness.

3. Manufacturing and Packaging:

- Production Efficiency: Viscosity affects the ease of production and filling processes. A product with a suitable viscosity can be efficiently processed and packaged without clogging or causing production delays.

- Packaging Compatibility: The viscosity of a product dictates the appropriate packaging type. A thick cream might require a jar, while a thin serum might be suitable for a dropper bottle.

Techniques for Measuring Viscosity in Cosmetics

Measuring viscosity is a crucial step in cosmetic product development and quality control. Several methods are available, each with its own advantages and applications:

1. Rotational Viscometers:

- Principle: Rotational viscometers measure viscosity by determining the torque required to rotate a spindle immersed in the fluid. The spindle rotates at a controlled speed, and the resistance to rotation is measured.

-

Types: There are various types of rotational viscometers, including:

- Cone and Plate: This method uses a cone-shaped spindle rotating on a flat plate, ideal for measuring low-viscosity fluids like serums and lotions.

- Cylindrical Spindles: These spindles rotate within a cylindrical sample container, suitable for measuring higher viscosity products like creams and masks.

- Brookfield Viscometer: A popular type of rotational viscometer used for measuring the viscosity of various fluids, including cosmetics.

- Advantages: Rotational viscometers offer high accuracy, versatility, and are suitable for a wide range of viscosities.

- Disadvantages: Can be expensive, require careful calibration, and may not be suitable for very low viscosity products.

2. Vibrational Viscometers:

- Principle: Vibrational viscometers measure viscosity by analyzing the damping of an oscillating element immersed in the fluid. The viscosity is determined by the frequency and amplitude of the oscillations.

- Advantages: Vibrational viscometers are compact, portable, and suitable for measuring low-viscosity fluids. They are also relatively insensitive to temperature changes.

- Disadvantages: May have limited accuracy compared to rotational viscometers and are not ideal for high-viscosity products.

3. Capillary Viscometers:

- Principle: Capillary viscometers measure viscosity by measuring the time it takes for a specific volume of fluid to flow through a capillary tube under gravity.

- Advantages: Capillary viscometers are simple, inexpensive, and suitable for measuring Newtonian fluids (fluids with constant viscosity).

- Disadvantages: Not suitable for non-Newtonian fluids (fluids with variable viscosity), require careful temperature control, and are less accurate than other methods.

4. Falling Ball Viscometer:

- Principle: This method measures the time it takes for a ball to fall through a specific distance in the fluid. The viscosity is determined by the ball’s terminal velocity.

- Advantages: Falling ball viscometers are relatively simple and suitable for measuring high-viscosity fluids.

- Disadvantages: Not suitable for low-viscosity fluids, can be time-consuming, and may require calibration.

5. Ostwald Viscometer:

- Principle: This method measures the time it takes for a specific volume of fluid to flow through a capillary tube under gravity. The viscosity is determined by the time it takes for the fluid to flow between two marked points.

- Advantages: Simple and inexpensive, suitable for measuring Newtonian fluids.

- Disadvantages: Not suitable for non-Newtonian fluids, require careful temperature control, and are less accurate than other methods.

6. Rheometers:

- Principle: Rheometers measure the flow behavior of fluids under different stress conditions. They can determine the viscosity of fluids over a range of shear rates, providing a comprehensive understanding of the fluid’s rheological properties.

- Advantages: Rheometers offer the most comprehensive analysis of fluid behavior, providing valuable insights into the viscoelastic properties of cosmetic products.

- Disadvantages: Rheometers are complex, expensive, and require specialized expertise to operate.

Factors Affecting Viscosity Measurement

Several factors can influence viscosity measurement, affecting the accuracy and reliability of the results:

- Temperature: Viscosity is highly sensitive to temperature. It generally decreases with increasing temperature. Therefore, maintaining a consistent temperature during measurement is crucial.

- Shear Rate: Non-Newtonian fluids exhibit varying viscosity depending on the shear rate. Therefore, it is essential to choose a suitable shear rate that represents the product’s intended use.

- Sample Preparation: The viscosity of a cosmetic product can be affected by factors like air bubbles, particulate matter, or improper sample homogenization. Proper sample preparation is essential for accurate measurements.

- Equipment Calibration: All viscometers require regular calibration to ensure accuracy. Calibration should be performed according to the manufacturer’s instructions.

Importance of Viscosity Measurement in Cosmetic Product Development

Measuring viscosity is a critical step in the development and production of cosmetics, ensuring:

- Consistency and Quality: Accurate viscosity measurement ensures that each batch of product meets the desired specifications, guaranteeing consistency in texture, spreadability, and performance.

- Formulation Optimization: By understanding the relationship between viscosity and product performance, formulators can optimize the formulation to achieve the desired sensory experience and efficacy.

- Stability and Shelf Life: Proper viscosity control contributes to the stability of the product, preventing separation, sedimentation, or changes in texture over time, extending the shelf life and maintaining product quality.

- Packaging Compatibility: Viscosity determines the appropriate packaging type, ensuring the product is easily dispensed and remains stable in the chosen container.

FAQs on Viscosity Measurement in Cosmetics

1. What is the ideal viscosity for a cosmetic product?

The ideal viscosity for a cosmetic product depends on its intended use and desired sensory experience. For example, a serum might require a lower viscosity for easy absorption, while a cream might need a higher viscosity for a richer texture.

2. How do I choose the right viscosity measurement method for my product?

The choice of method depends on the product’s viscosity, desired accuracy, and available resources. For low-viscosity products, vibrational or capillary viscometers may suffice. For higher viscosity products, rotational viscometers or falling ball viscometers are more appropriate.

3. What are the units of viscosity?

Viscosity is typically measured in units of centipoise (cP) or Pascal-seconds (Pa·s). 1 Pa·s = 1000 cP.

4. How do I ensure accurate viscosity measurements?

Accurate viscosity measurements require careful attention to temperature control, sample preparation, and equipment calibration. It is also important to choose a suitable shear rate that represents the product’s intended use.

5. How can I improve the viscosity of my cosmetic product?

The viscosity of a cosmetic product can be adjusted by adding thickeners or viscosity modifiers to the formulation. The choice of thickener depends on the desired texture and properties of the product.

Tips for Measuring Viscosity in Cosmetics

- Use a calibrated viscometer: Ensure the viscometer is properly calibrated according to the manufacturer’s instructions.

- Control temperature: Maintain a consistent temperature during measurement, as viscosity is sensitive to temperature changes.

- Prepare the sample correctly: Remove air bubbles, homogenize the sample, and ensure proper sample preparation for accurate results.

- Choose the appropriate shear rate: Select a shear rate that reflects the product’s intended use.

- Repeat measurements: Take multiple measurements to ensure consistency and accuracy.

- Record all data: Document all parameters, including temperature, shear rate, and measurement results for future reference.

Conclusion

Measuring viscosity is an essential aspect of cosmetic product development and quality control. It ensures consistency, optimizes formulation, and contributes to the overall sensory experience and performance of cosmetic products. By understanding the different methods of viscosity measurement and the factors that influence it, cosmetic manufacturers can ensure their products meet the highest standards of quality and consumer satisfaction.

.jpg)

Closure

Thus, we hope this article has provided valuable insights into The Significance of Viscosity in Cosmetics: Measuring the Flow of Beauty. We appreciate your attention to our article. See you in our next article!