The Science Of Hardening: Exploring The Properties And Applications Of Fast Skin Iron

The Science of Hardening: Exploring the Properties and Applications of Fast Skin Iron

Related Articles: The Science of Hardening: Exploring the Properties and Applications of Fast Skin Iron

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Science of Hardening: Exploring the Properties and Applications of Fast Skin Iron. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Science of Hardening: Exploring the Properties and Applications of Fast Skin Iron

The term "fast skin hard shock iron" is not a recognized scientific or industrial term. It is likely a colloquial or informal phrase used to describe a particular type of iron or steel known for its hardness and resistance to shock. This article aims to provide a comprehensive understanding of the properties and applications of iron and steel alloys that exhibit such characteristics, exploring the science behind their remarkable strength and resilience.

Understanding the Properties of Iron and Steel

Iron, a naturally occurring element, is the foundation of many materials used in modern society. Its ability to form alloys with other elements, particularly carbon, gives rise to a wide range of materials with diverse properties. Steel, an iron-carbon alloy, is particularly versatile, offering a spectrum of strength, ductility, and hardness depending on the carbon content and processing techniques.

Hardness: A Measure of Resistance

Hardness, a fundamental property of materials, refers to their resistance to indentation or scratching. In the context of iron and steel, hardness is directly related to the strength of the material’s atomic structure.

Shock Resistance: Withstanding Impact

Shock resistance refers to a material’s ability to absorb and dissipate energy from sudden impacts. This property is crucial for applications where materials are subjected to high-force collisions, such as in machinery, tools, and protective gear.

The Role of Processing Techniques

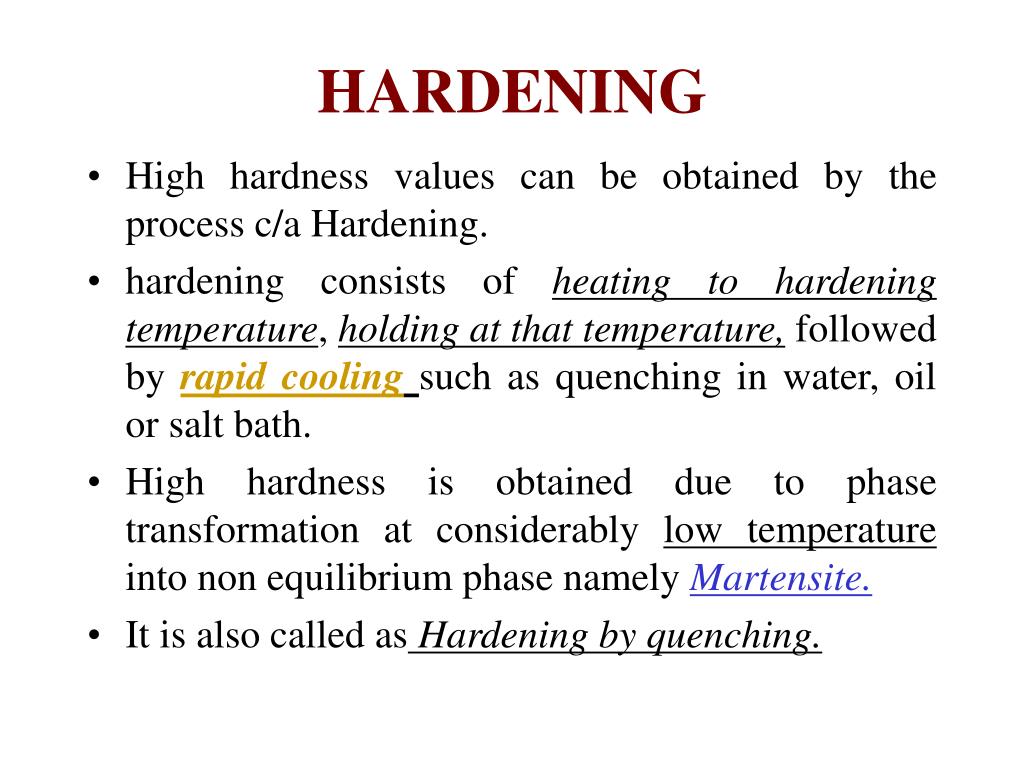

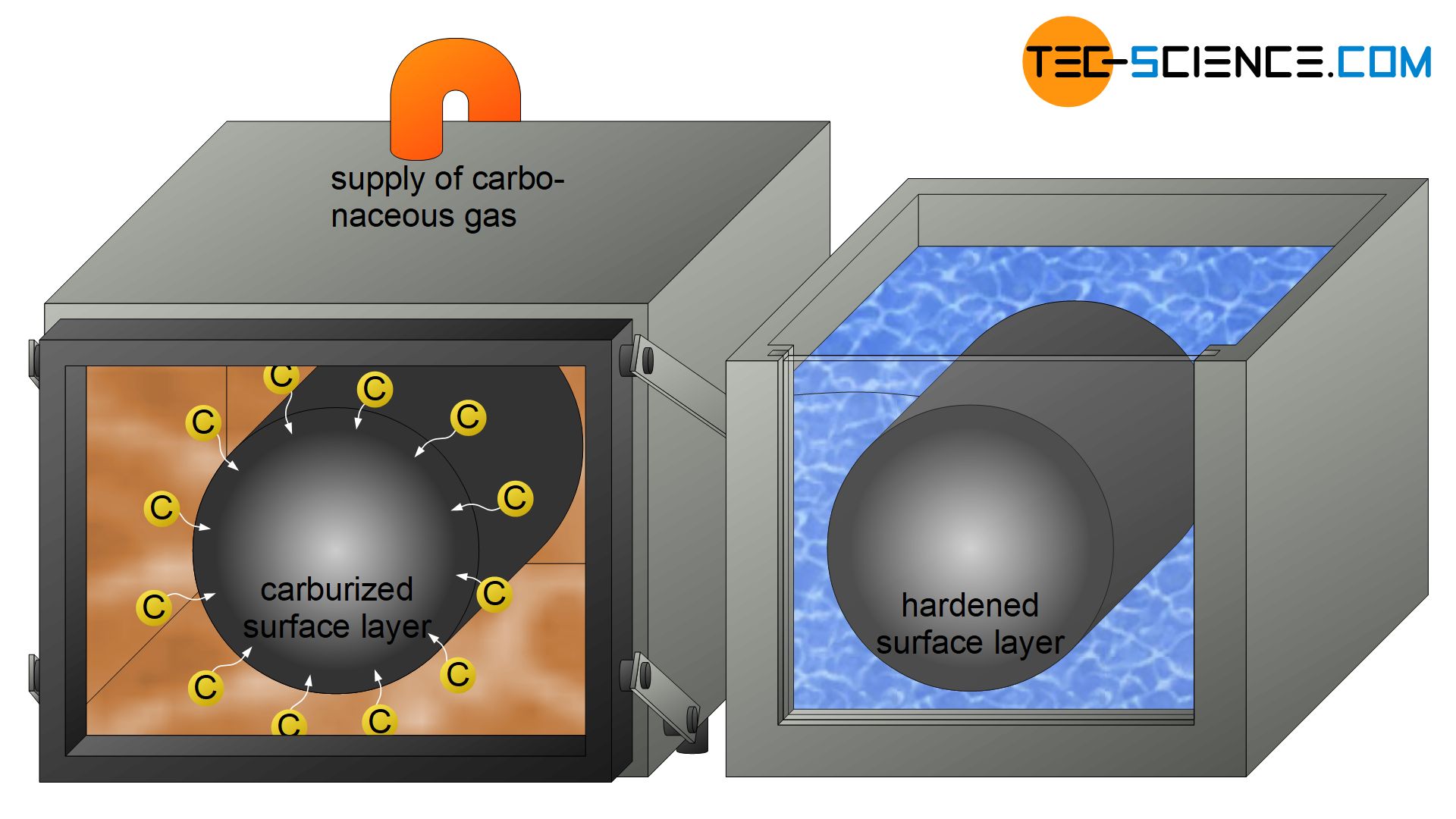

The hardness and shock resistance of iron and steel are not solely determined by their composition. Processing techniques play a crucial role in shaping the material’s microstructure and, consequently, its mechanical properties.

- Heat Treatment: Heat treatment processes, such as annealing, quenching, and tempering, involve controlled heating and cooling cycles to manipulate the material’s crystalline structure. These processes can significantly enhance hardness and shock resistance.

- Cold Working: Cold working involves deforming the material at room temperature, which strengthens the material by introducing internal stresses. This process increases hardness but can reduce ductility.

Applications of Hardened Iron and Steel

The combination of hardness and shock resistance in iron and steel makes them ideal for various applications:

- Tools and Machinery: Hardened steel is used in tools like chisels, hammers, and cutting blades, where resistance to wear and impact is paramount. It is also used in machinery components like gears, axles, and bearings, ensuring durability and longevity.

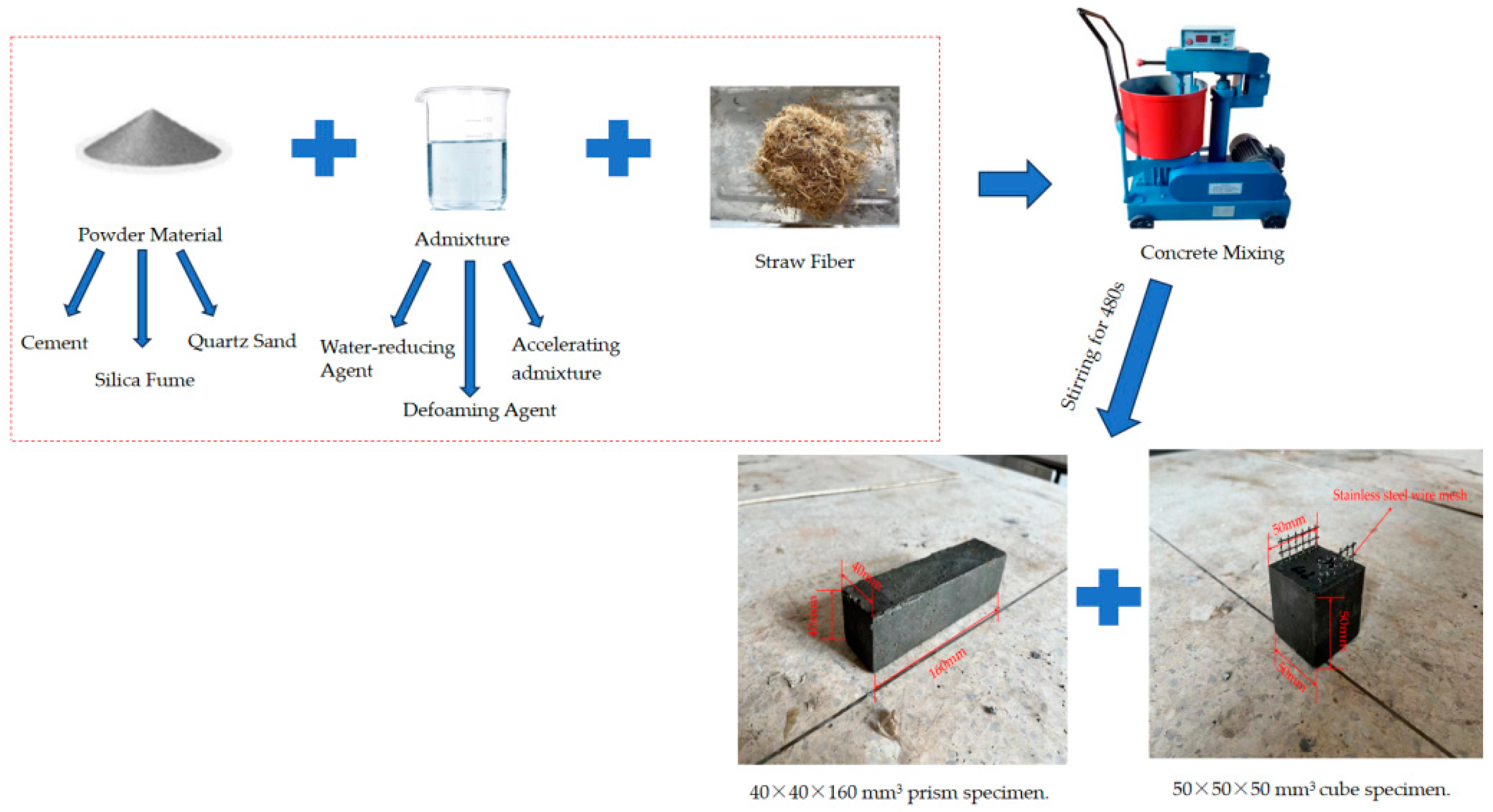

- Construction: Steel reinforced concrete is a common structural material, where the high strength of steel bars provides reinforcement against tension and impact.

- Protective Gear: Hardened steel is found in protective gear like helmets, body armor, and safety equipment, offering vital protection against impacts and penetration.

- Automotive: Hardened steel is used in vehicle components like engine blocks, chassis frames, and suspension systems, ensuring structural integrity and impact resistance.

Exploring Specific Alloys

While the term "fast skin hard shock iron" is not a recognized term, several specific iron and steel alloys exhibit exceptional hardness and shock resistance.

- High-Carbon Steel: High-carbon steel alloys, with carbon content exceeding 0.6%, are known for their high hardness and wear resistance. They are often used in tools and machinery requiring high durability.

- Tool Steel: Tool steels are a specialized class of high-carbon steel alloys, specifically designed for tool applications. They often incorporate additional elements like chromium, molybdenum, and tungsten to enhance their hardness, wear resistance, and toughness.

- Maraging Steel: Maraging steels are known for their high strength and toughness, achieved through a unique aging process. They are often used in aerospace and defense applications where high strength and impact resistance are crucial.

- High-Strength Low-Alloy (HSLA) Steel: HSLA steels offer a balance of strength, ductility, and weldability. They are widely used in construction and automotive applications, providing strength and impact resistance without sacrificing formability.

FAQs

1. What are the benefits of using hardened iron and steel in tools and machinery?

Hardened iron and steel offer significant benefits in tools and machinery:

- Increased Durability: Hardness and shock resistance ensure the tools and machinery components can withstand repeated use and impact without damage or deformation.

- Improved Performance: Hardened materials resist wear and tear, maintaining sharp cutting edges and smooth surfaces for optimal performance.

- Extended Service Life: The increased durability translates to longer service life, reducing the need for frequent replacements and minimizing downtime.

2. How is the hardness of iron and steel measured?

The hardness of iron and steel is typically measured using standardized tests:

- Rockwell Hardness Test: This test involves indenting the material with a diamond cone or steel ball under a specific load. The depth of indentation is measured and correlated to a hardness value.

- Brinell Hardness Test: This test uses a hardened steel ball to indent the material under a specific load. The diameter of the indentation is measured and used to calculate the hardness value.

- Vickers Hardness Test: This test utilizes a diamond pyramid indenter to create an indentation under a specific load. The area of the indentation is measured to determine the hardness value.

3. What are the factors that influence the shock resistance of iron and steel?

Several factors contribute to the shock resistance of iron and steel:

- Material Composition: The specific elements and their proportions in the alloy influence its strength and toughness, which directly impact shock resistance.

- Microstructure: The arrangement of grains and phases within the material’s structure affects its ability to absorb and dissipate energy from impacts.

- Processing Techniques: Heat treatment and cold working processes can significantly influence the microstructure and, consequently, the shock resistance of the material.

Tips for Selecting Hardened Iron and Steel

- Specify the Application: Define the specific requirements of the application, including the expected loads, impact forces, and wear conditions.

- Consider the Material Properties: Choose a material with appropriate hardness, shock resistance, and other relevant properties for the intended application.

- Consult with Experts: Consult with material scientists or engineers to select the most suitable material and processing techniques for your specific needs.

- Perform Testing: Conduct appropriate hardness and impact tests to verify the chosen material meets the required specifications.

Conclusion

The search for materials with exceptional hardness and shock resistance has driven the development of advanced iron and steel alloys. Through controlled processing techniques and careful material selection, engineers can create materials that withstand extreme forces and impacts, ensuring the durability and reliability of tools, machinery, and protective gear. While the term "fast skin hard shock iron" may not be a recognized scientific term, it encapsulates the desire for materials that exhibit remarkable strength and resilience, enabling us to build a more robust and reliable world.

Closure

Thus, we hope this article has provided valuable insights into The Science of Hardening: Exploring the Properties and Applications of Fast Skin Iron. We hope you find this article informative and beneficial. See you in our next article!